Is barcode Code39 scanning reliable?

Categories:

Is Barcode Code39 Scanning Reliable?

Explore the reliability of Code39 barcodes, their strengths, limitations, and best practices for ensuring accurate scanning in various applications.

Code39, also known as Code 3 of 9, is one of the oldest and most widely used alphanumeric barcode symbologies. Developed in 1974, it's a variable-length, self-checking barcode that can encode uppercase letters (A-Z), digits (0-9), and a few special characters (-, ., $, /, +, %, and space). Its simplicity and broad adoption make it a common choice for inventory management, asset tracking, and various industrial applications. But how reliable is it in practice?

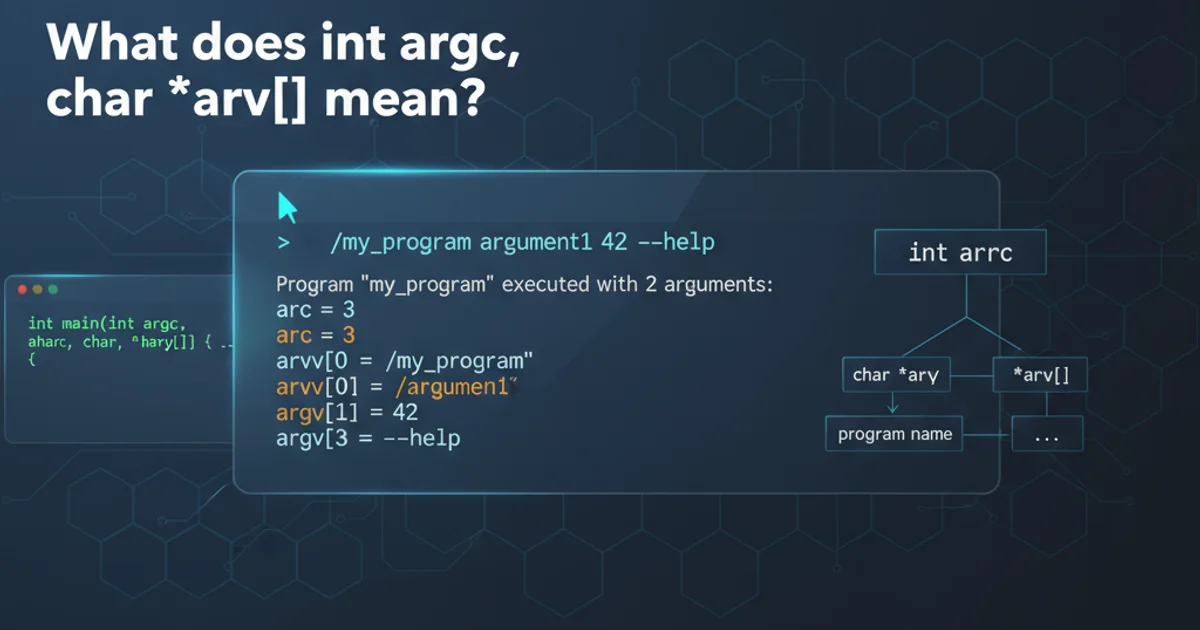

Understanding Code39 Structure and Reliability Factors

Code39 encodes each character using nine elements: five bars and four spaces. Three of these nine elements are wide, and six are narrow. This '3 of 9' structure gives the barcode its name. A key feature contributing to its reliability is its self-checking nature, meaning a single read error is unlikely to result in a misread character. Each character has a unique pattern, reducing the chance of one character being mistaken for another due to minor print defects or scanning imperfections.

flowchart LR

A[Input Character] --> B{Encode Character}

B --> C[Generate 9-Element Pattern]

C --> D{3 Wide, 6 Narrow?}

D -- Yes --> E[Add Start/Stop Character]

E --> F[Print Barcode]

F --> G[Scan Barcode]

G --> H{Decode 9-Element Pattern}

H -- Valid --> I[Output Character]

H -- Invalid --> J[Error/Rescan]

D -- No --> JCode39 Encoding and Decoding Process Flow

While Code39 is robust, its reliability can be influenced by several factors:

- Print Quality: Poor print quality (low contrast, smudges, voids, or excessive ink spread) can significantly degrade scan reliability. Faded labels or labels printed on reflective surfaces also pose challenges.

- Barcode Size and Density: Code39 is a low-density symbology, meaning it requires more space to encode data compared to higher-density barcodes like Code128. If the barcode is too small or printed at too high a density for the printer/scanner, reliability can suffer.

- Scanner Type and Quality: The type and quality of the barcode scanner play a crucial role. Laser scanners, CCD imagers, and 2D imagers each have different strengths and weaknesses regarding reading damaged or poorly printed barcodes.

- Environmental Conditions: Lighting conditions, temperature, and humidity can affect both the barcode label itself and the scanner's performance. Glare, extreme temperatures, or dirty scanning environments can reduce reliability.

- Damage to Barcode: Creases, tears, scratches, or abrasions on the barcode can make it unreadable or lead to misreads.

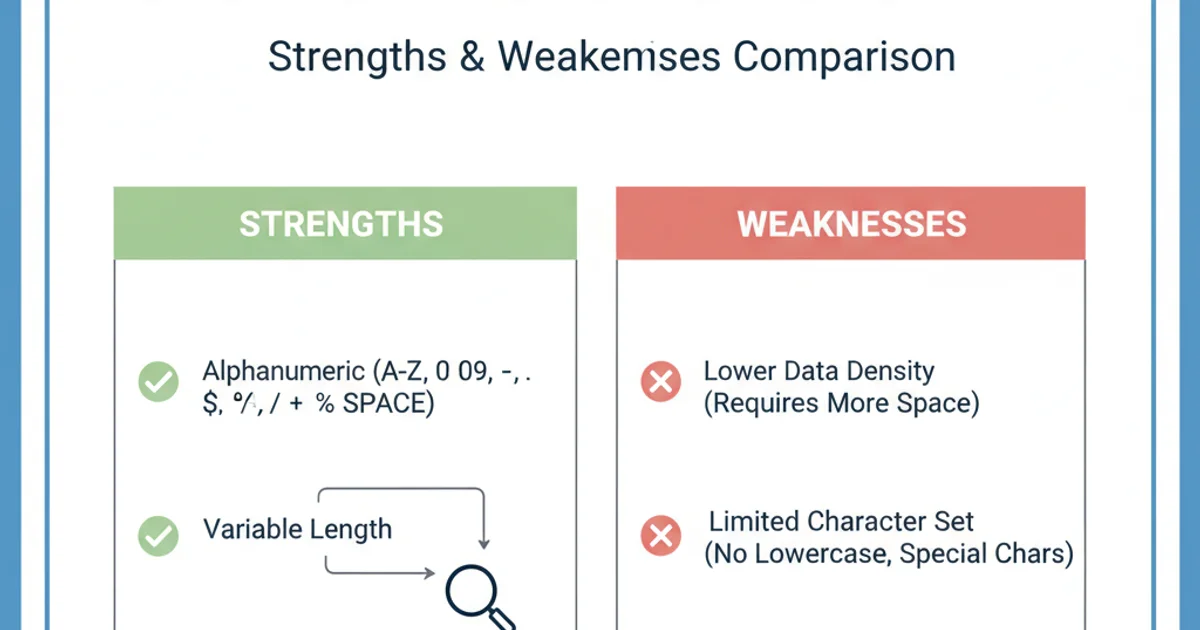

Strengths and Limitations of Code39

Code39's enduring popularity stems from its key strengths, but it also comes with certain limitations that users should be aware of.

Strengths and Weaknesses of Code39

Strengths:

- Alphanumeric Support: Can encode letters, numbers, and some special characters, making it versatile for various data types.

- Self-Checking: Each character's unique pattern reduces the likelihood of misreads from minor print defects.

- Simple Structure: Relatively easy to print and decode, contributing to its widespread adoption.

- Variable Length: No fixed data length, allowing for flexibility in encoding.

- Widely Supported: Almost all barcode scanners and software support Code39.

Limitations:

- Low Data Density: Requires more physical space to encode the same amount of data compared to more modern symbologies like Code128 or QR codes.

- Limited Character Set: Does not support lowercase letters or a full range of special characters without using Code39 Full ASCII, which can be less universally supported.

- No Built-in Check Digit (Standard): While Mod 43 can be added, it's not an inherent part of the basic Code39 specification, meaning standard Code39 offers less error detection than symbologies with mandatory check digits.

Best Practices for Maximizing Code39 Reliability

To ensure the highest possible scanning reliability with Code39 barcodes, follow these best practices:

1. Ensure High Print Quality

Use high-resolution printers and quality label stock. Maintain proper contrast between bars and spaces (dark bars on a light background). Regularly clean printer heads.

2. Optimize Barcode Size

Print barcodes at an appropriate size for the data encoded and the scanning environment. Avoid making them too small, which can lead to unreadable elements.

3. Choose the Right Scanner

Select a scanner appropriate for your application. For industrial environments or damaged barcodes, a 2D imager might offer better performance than a basic laser scanner.

4. Maintain Cleanliness

Keep both the barcodes and the scanner's reading window clean. Dust, dirt, or smudges can interfere with accurate scanning.

5. Implement Check Digits (Optional but Recommended)

If data integrity is paramount, use Code39 Mod 43 to add a check digit, which helps detect common data entry or scanning errors.

6. Proper Placement and Protection

Place barcodes on flat, non-creased surfaces. Consider laminating or using protective coatings for labels in harsh environments to prevent damage.